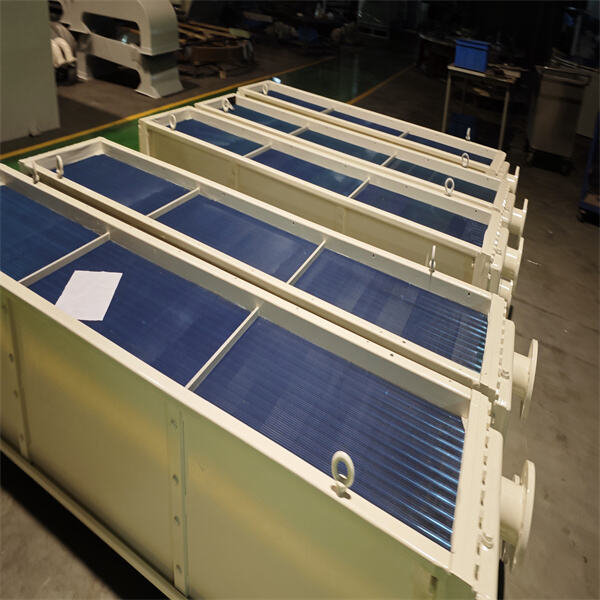

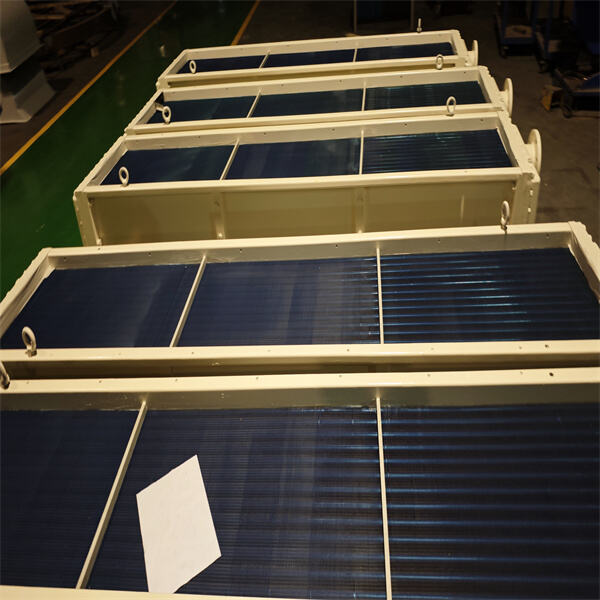

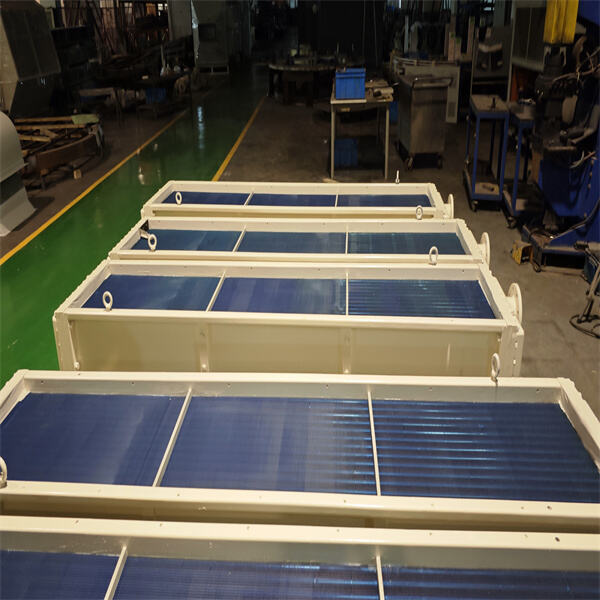

Heat Exchangers are these wonderful machines that help transfer heat from one location to another. They play significant roles in several diverse industries where they can conserve energy while making business processes smoother. Rich aluminum fin heat exchanger — This is one among the most common heat exchangers used. Keep reading to know more about what these devices are and how they work. Aluminium plate fin heat exchangers, as a form of a heat exchanger, can transfer the energy in the hot fluid to cold fluid or vice versa without mixing them together. It is a matter of layers of thin plates, each oriented in some definite direction. This unique placement of the cells then creates channels or paths that fluid can traverse. These grooves have hidden fins in them, which are sort of miniature spikes that enlarge the surface of the plates. High surface area facilitates a better heat transfer with little loss by permitting a good flow of heat between the fluids.

Aluminum plate fin heat exchangers are ideal for use in various industries, and they are very good for many reasons. The main advantage is that they have better efficiency. They are also designed to provide the highest heat transfer rates, thus saving a lot of energy. Businesses become more profitable, so prices can be lower. They are also very rigid and do not corrode, which makes them ideal in harsh environments where many other materials would simply fail. The versatility of these heat exchangers is another great advantage. They are used in a wide range of applications from heating and cooling systems to various chemical processes. They are also designed to be small and lightweight, which makes them quite versatile to plumb different spots and carry about if need be. This ability is useful, but in companies that require machines to undertake different functions, it can be even more helpful.

An important application of aluminum plate fin heat exchangers is cooling the steam which is formed during the energy generation in power plants. These Rich brazed aluminum plate fin heat exchangers cool the steam so efficiently that they help to improve the efficiency of power generation in general. This means that some saving energy better for both mother nature and the P and L as well.

These heat exchangers are also highly important in the chemical manufacturing field. Instead, they cool and condense chemicals as they are being developed in the manufacturing process. Regarding these chemicals, fewer amounts of energy are required to cool them by using aluminum plate fin heat exchangers. This Saves cost in a way, increases the effectiveness that eases manufacturing process.

The Aluminum Plate Fin Heat Exchanger — designed for high-pressure applications demanding durability and energy efficiency. Rich brazed aluminium heat exchanger is commonly used for cooling and condensing gas that comes out of the oil-drilling process. Chemical Heat Exchanger: At the same time, these heat exchangers are also discovered within chemical processing plants where cooling and condensing of various chemicals manufactured in those facilities.

The firms has always Aluminum plate fin heat exchanger and scientific advancement to enhances its core competitiveness. The annual research and developments expenses account for 5percents. The company also has a staff of professionals, top-quality, innovative, and pragmatics research and developments talent. The company's engineering and technical staff are more than 20 percent.

The Aluminum plate fin heat exchanger is normally in a position to provide customers with one-stop solutions as well because all-inclusive product service and a pre-sales team of experts in technical areas to produce customers and design and system cooperation solutions; Sales has a qualified technicians, supervisors and manufacturing personnel to give process control, installation guidance and technical training also as commissioning and inspection. After-sales service includes a dedicated site that analyzes quality issues after sales swift response and handling of quality dilemmas that arise on-site, and long-term enhancement of design.

ShangHai Rich M and E Manufacturing Co., Ltd. Established in 1998, is a business that has been operating for 20 years. Since then, it has becomes an Aluminum plate fin heat exchanger in the manufacture of a wide ranges of products such as coolers and power collections rings, water treatment devices, railway maintenance, intelligent diagnosis online monitoring, as well as other systems and products.

Aluminum plate fin heat exchanger has expert technical technicians, production and management staff for process control and guidance that is technical installation in commissioning, inspection and maintenance. After-sales services have a passionate team this is certainly responsible for issues that arise after sales, fast response and treatment issues that is on-site long-term improvements of product system design.

Copyright © ShangHai Rich M & E Manufacturing Co., Ltd. All Rights Reserved - Privacy policy