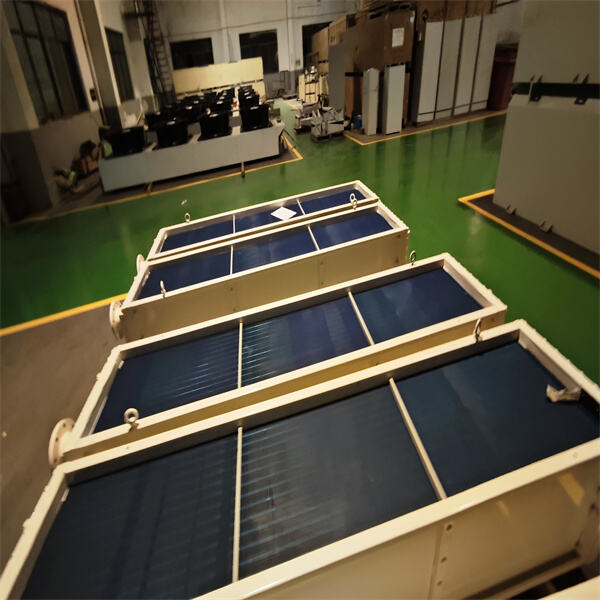

A cooler exchanger is a machine designed primarily to help transfer heat from the fluid/solid and to air. That liquid can be basically anything, such as water or oil. All kinds of cooler exchangers are used, such as in air conditioning systems, cooling machines and refrigerators. They help keep things the correct temperature, a necessity for many tasks.

The use of Rich Air fin cooler heat exchanger is to make it easier for heat to flow from the liquid to the air. To achieve this, they increase the exposure of liquid to air and expel the air over the liquid. Cooling exchangers enhance the rate of heat transfer by ensuring that more air comes into contact with the liquid, thus allowing it to cool down faster.

The cooler exchanger saves a considerable amount of energy. The cooler exchanger extracts heat from the liquid, and then releases that into the air, so it requires less energy to keep everything at the proper temperature. Businesses can lower their costs and reduce their carbon footprint of businesses making a positive impact to our planet.

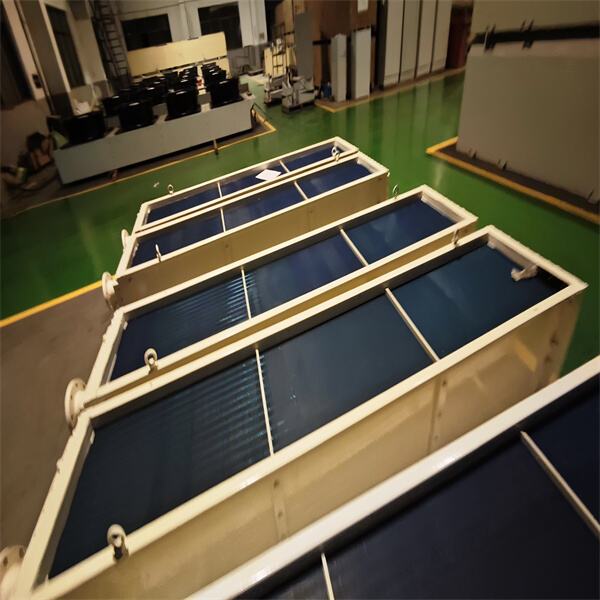

This is also used by cooler exchanger factory to work better as well as faster. Those are definitely useful for manufacturing since they stay at a constant temperature, Cold heading improves quality and reduces downtime because of fewer issues with the quality of materials as temperatures remain constant, leading to lesser chances that machines will break down unexpectedly. And this ensures that workers can continue executing their actions without any malfunction of the equipment with Rich Air cooled fin fan heat exchanger.

A cooler exchanger simply shuffles hot fluid into the air. This is critical to prevent the systems from over-heating– a situation that can damage equipment, or even worse. Cooler exchangers help companies prevent costly repairs and downtime, by guaranteeing the system runs smoothly and efficiently. Moreover, they conserve energy as well that is not only a way where you save money but it also helps to care for the environment with Rich cooler heat exchanger.

If, for instance, the liquid you are handling contains corrosives or other dangerous elements related to its contents depending on your needs you could be a cooler exchanger of high resistance material with stainless steel. For facilities with space constraints, choose a smaller cooler exchanger. Ultimately, you want to select a cooler exchanger that fits well, operates efficiently and keeps everything at the optimal temperature.

A cooler exchanger can be beneficial for your system but choosing the right one is another dilemma itself, considering the several factors in charge of providing it high performance. Traditionally, businesses find the most appropriate way to dispose of Certificates for landfill – which costs them time and money – but also generates unnecessary waste.

The Cooler exchanger is unquestionably in a position to provide customers with one-stop systems as well as the life-cycle that is full of services Professional pre-sales staff of technical experts to provide customers with design and system cooperation systems; Sales have professional technical, managerial and production personnel team to produce process control, installation assistance and assistance this is certainly technical in addition to commissioning and inspection. The provider that will be after-sales a service that is particular that analyzes quality issues after sales swift response and management of on-site quality problems, as well as long-lasting improvements to your design.

The Cooler exchanger is definitely able to provide customers with a solution which was single-stop the full life-cycle of product services Pre-sales professionals team of technical experts who provide customers with design services along with system cooperation services. Sales has an expert technical, production plus management staff to give you control over processes, installation guidance and technical assistance in addition to commissioning and inspection. services has a special service that analyzes quality issues after sales rapid response quality of on-site quality problems, and long-term improvement of this product system design.

The company always insists on using technological and Cooler exchanger to improves its core competitiveness. The annual research and developments expenses account for 5% of sales. The company also has a workforces that is professionals, high-quality efficient, creative and pragmatic research and development talents. The company's engineering and technical staff is over 20 percent..

ShangHai Rich M and E Manufacturing Co., Ltd. Cooler exchanger, is a company that has been running for 20 years. Since then, it has become a manufacturers of a variety of products such as coolers as well as powers collecting rings. railways maintenance, intelligent diagnosis, online monitoring, as well as other systems and products.

Copyright © ShangHai Rich M & E Manufacturing Co., Ltd. All Rights Reserved - Privacy policy