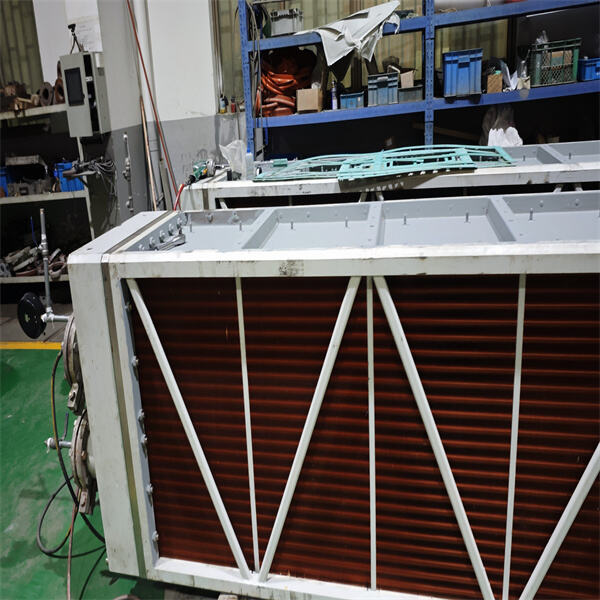

Heat exchangers are devices that allow the transfer of heat from one fluid (liquid or gas) to another. These are available in many household items such as air conditioners, refrigerators. Ever since The Dawn of Man, we've been using machines that transfer heat—something very useful when it comes to cooling or heating spaces. The parts that are unique for fin heat exchangers are known as fins. The function of these fins is like a little antenna that accepts heat and excels at moving it into the chilling machines is also more efficient to work on by this. Fin heat exchangers are applied in varied sites. They are used in buildings to provide thermal comfort and in power plants as well. They're big simply because they're great at moving a lot of heat in a small area. Which is critical, as often this will be an obstacle we need to overcome. The fins permit these heat exchangers to work their magic without occupying excessive room, so it an excellent quick remedy for limited or jam-packed areas.

Well, now let's dive in discussion to some of the differences there is between fin heat exchangers and plate heat exchangers. While fin heat exchangers need fins to help heat transfer, plate heat exchangers use flat plates. Said plates are assembled such that channels for the liquid to flow inside move stacked upon each other. That way the fluids can move and heat transfer is possible. In several industrial applications, there is a high demand to move heat from one location to another and respect for saving energy is highly recommended. With a greater surface area for transferring heat, fin heat exchangers also put energy to work. In other words, they are more efficient at moving heat with less energy; something that is good for the environment and for companies looking to reduce their operational costs.

Well, now let's dive in discussion to some of the differences there is between fin heat exchangers and plate heat exchangers. While fin heat exchangers need fins to help heat transfer, plate heat exchangers use flat plates. Said plates are assembled such that channels for the liquid to flow inside move stacked upon each other. That way the fluids can move and heat transfer is possible. In several industrial applications, there is a high demand to move heat from one location to another and respect for saving energy is highly recommended. With a greater surface area for transferring heat, fin heat exchangers also put energy to work. In other words, they are more efficient at moving heat with less energy; something that is good for the environment and for companies looking to reduce their operational costs.

Industrial Plate Heat Exchangers provide many benefits They are very efficient and can transfer a lot of heat into a small space. In industries that need to maximize efficiency of time, space and costs, this is significant. Plus, plate industries are generally simpler to clean and maintain than other warm transfers, leading to decreased downtime including increased operational efficiency.

Flexibility is another advantage of plate heat exchangers. They can be configured to fulfill unique application requirements. For instance, they cover a variety of applications because are capable to manage several flow rates and temperature ranges. They can also be versatile as they are used in a number of processes, right from food processing to chemical manufacturing.

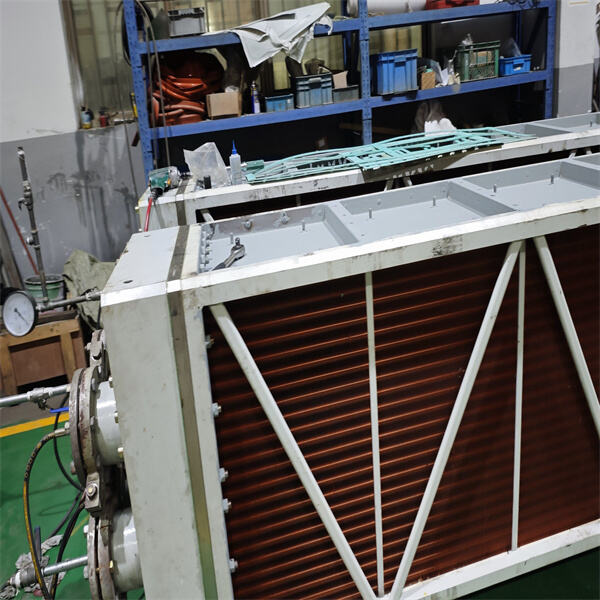

The firms has always Fin and plate heat exchanger and scientific advancement to enhances its core competitiveness. The annual research and developments expenses account for 5percents. The company also has a staff of professionals, top-quality, innovative, and pragmatics research and developments talent. The company's engineering and technical staff are more than 20 percent.

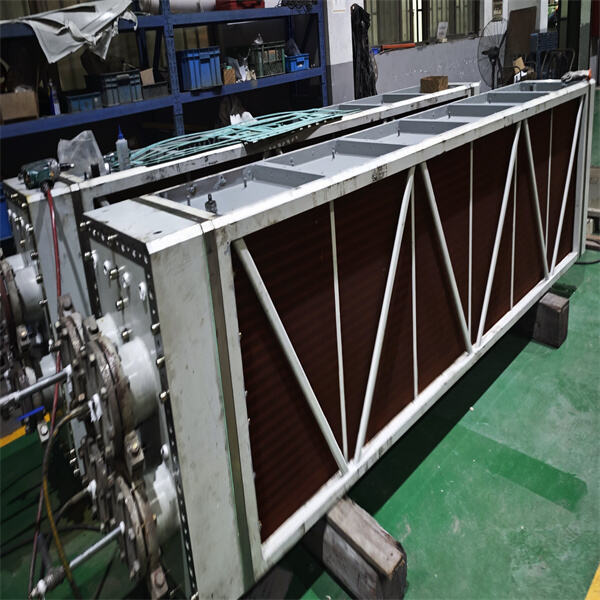

Fin and plate heat exchanger employs highly trained technical technicians, production and management staff to supply process control, technical guidance for installation for commissioning plus inspection. After-sales services have a special team problems that arise after sales, fast response and treatment on-site problems and long-term improvements of product system design.

ShangHai Rich M and E Manufacturing Co., Ltd. was established in 1998, after Fin and plate heat exchanger, has developed into a collections of all kinds of coolers including power collections rings water treatment devices railway maintenance monitoring online, intelligent diagnosis, as well as other products as well as research and developments for systems and production as a parts of the business, the company's products are extensively used in powers stations railroads heavy industry, and many other areas.

Fin and plate heat exchanger has experienced team that is technical production and management to make sure process control along with installation guidance, technical instruction for commissioning and examination. After-sales support includes a bunch this is certainly special post-sales analysis of problems, speedy intervention and resolution of problems on webpages along with long-term improvements to your system design.

Copyright © ShangHai Rich M & E Manufacturing Co., Ltd. All Rights Reserved - Privacy policy