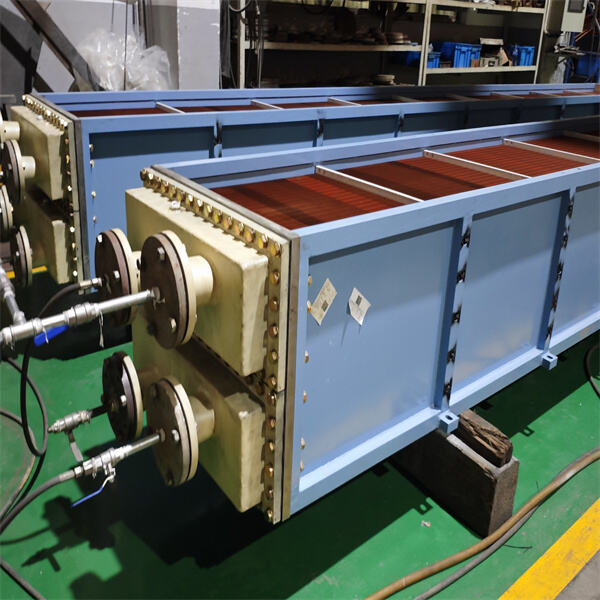

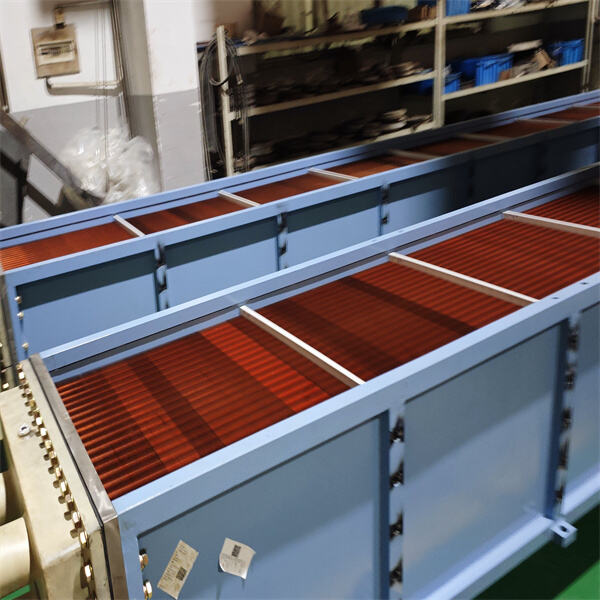

Plate Fin Exchangers Plate fin exchangers serve to move heat from one fluid to another. A thin metal sheet (fins as shown) are the key to this effort. Those fins make for more surface area for heat to travel across, which also means the machines are especially good at what they do. With this unique design, plate fin exchangers find extensive usages across various application limits. They can be found in power plants, oil factories and even on airplanes.

Moreover, one awesome advantage of Air cooler fins from Rich is how efficiently they work. They can easily move a heat from one place to another in short time and with less energy. Therefore, they can save energy as they work without consuming a lot of resources. They are small and have a compact size advantage. Plate fin exchangers are relatively among the ones which are very compact, meaning they own very less ground area. This really comes in handy when the room to work is minimal like a factory, or machine room. Smaller machines also have a role, particularly where space is at a premium.

The working principle of a plate fin exchangers is the fluid heat being transported from one liquid to another. That will have the effect of cooling it down like in a car radiator where the heat is drawn out away from the engine so as not to overheat. But they can also warm a thing, like for example heating fluids – as with a boiler where water or other liquid is warmed. Because the Rich exchangers have fins very thinly, they make heat transfer more easily from one liquid to another. Furthermore, the liquids involved tend to flow rapidly, which aids in the faster delivery of heat. Liquid gains earn well, as fluids move faster and can exchange heat tremendously enhanced.

It does not matter whether the heat is to be moved between gas or liquid, what matters only in this plate fin exchanger is that there must be heat to be transferred between two different types of liquids. Normally, there are two different compartments, one for each liquid. While they follow different paths, the two liquids come into contact with each other via the thin fins. That is, although it's flowing within its own tubing and the liquids are not mingling, heat can still migrate from one liquid to another because they are in close proximity. Due to the temperature gradient between two liquids, heat is transferred from the hotter liquid to the cooler liquid. That is how the Airfin cooler and heat exchange works.

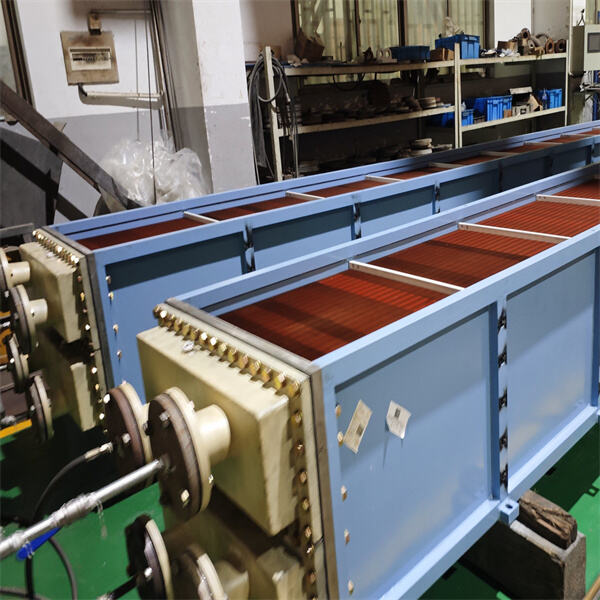

Plate fin exchangers cover many jobs and industries — oil and gas, power generation, aerospace just to name a few. They help in the reduction of drilling fluids during drilling like in the oil and gas industry. This helps to maintain the grind and increase safety. In powerplants, plate fin exchangers are employed to transfer heat from steam to water in order to facilitate the generation of electric power through turbines. One way they are used is by cooling down the engines of airplanes in the aerospace industry, which is important for the overall safety and efficiency of them while in flight.

We also proud to provide plate fin exchangers which are of high quality and can be put to use in various applications. Machines are intended to be efficient and reliable, they perform nicely and do their job. The Rich Fin fan cooler heat exchanger are small in the size, and it will be very easy to install so they can be installed in different places. From anything as simple as a plate fin exchanger to help lower the temperature of liquids, to ones that work for heating them up – we have just what you need.

The company is always using technological and Plate fin exchanger to enhances its cores competitiveness. Annual research and developments costs account for five percent of sales. The company also has a staff of professional, top-quality efficient, creative and pragmatic researchers and developers. The engineering and technical personnels is more than 20%.

The Plate fin exchanger is definitely able to provide customers with a solution which was single-stop the full life-cycle of product services Pre-sales professionals team of technical experts who provide customers with design services along with system cooperation services. Sales has an expert technical, production plus management staff to give you control over processes, installation guidance and technical assistance in addition to commissioning and inspection. services has a special service that analyzes quality issues after sales rapid response quality of on-site quality problems, and long-term improvement of this product system design.

The Plate fin exchanger is unquestionably in a position to provide customers with one-stop systems as well as the life-cycle that is full of services Professional pre-sales staff of technical experts to provide customers with design and system cooperation systems; Sales have professional technical, managerial and production personnel team to produce process control, installation assistance and assistance this is certainly technical in addition to commissioning and inspection. The provider that will be after-sales a service that is particular that analyzes quality issues after sales swift response and management of on-site quality problems, as well as long-lasting improvements to your design.

ShangHai Rich M and E Manufacturing Co., Ltd. was established in 1998, after Plate fin exchanger, has developed into a collections of all kinds of coolers including power collections rings water treatment devices railway maintenance monitoring online, intelligent diagnosis, as well as other products as well as research and developments for systems and production as a parts of the business, the company's products are extensively used in powers stations railroads heavy industry, and many other areas.

Copyright © ShangHai Rich M & E Manufacturing Co., Ltd. All Rights Reserved - Privacy policy