Collector ring materials and manufacturing: choosing the best solution to optimize performance

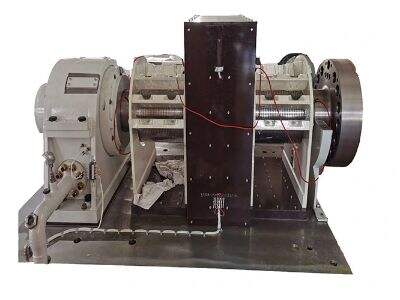

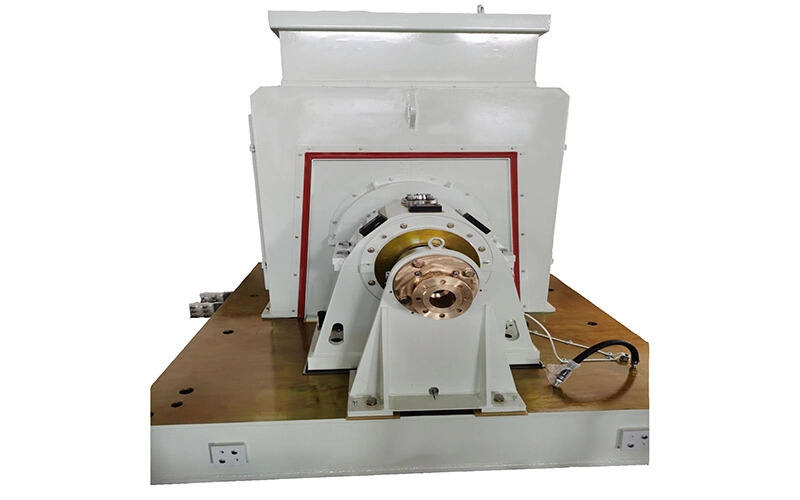

Collector ring materials and manufacturing are key elements to take into consideration when optimizing performance. The Rich collector ring is the employed unit to move electrical power signals between stationary and rotating parts. These rings are often found in many devices being commercial starting from wind turbines to cranes. We are going to discuss the different types of collector ring materials and manufacturing solutions available, their advantages and how to find the best solution to optimize efficiency.

Types of Materials and Manufacturing Solutions

You will discover a few materials based in the manufacturing of collector rings, including copper, silver, gold and graphite. Copper is one of the absolute most favored materials, due to its higher conductivity and wear good resistance. Gold and silver will also be very conductive, nevertheless they is much more costly than copper. Graphite is another popular material for low-current applications, as it has excellent self-lubricating properties.

Manufacturing solutions could also differ dependent on the application. Some offer typical manufacturing molding, die casting and machining. Injection molding is frequently put for mass creation of plastic collector rings, although die casting is used for steel rings. Machining is a precision manufacturing often method useful for tiny manufacturing runs or highly collector customized.

Advantages of Collector Ring Materials

Copper is one of the most used collector ring materials due to its high conductivity, good wear opposition and lower price. It is also super easy to device and has good properties which are technical. Gold and silver tend to be more costly but need also higher conductivity and lower resistance. They are utilized in high-current applications whenever efficiency is critical.

Graphite is an interesting materials collector rings due to the self-lubricating properties. It may withstand high conditions and is resistant to wear, rendering it the good decision applications whenever regular maintenance difficult.

Innovation in Collector Ring Manufacturing

In past times few years there's been significant innovation the manufacturing of collector rings. One innovation such the use of 3D publishing. This technology enables designers generate geometries which are complex weren't feasible and old-fashioned manufacturing methods. In addition, permits the production of small-batch customized collector rings quickly and cost-effectively.

Another innovation is the use of nanotechnology. The properties regarding the Toner collection device might be enhanced, such as improved conductivity and increasing wear by incorporating nanoparticles to the material. Nanoparticles also can reduce friction and increase the general efficiency of collector ring.

Safety Considerations

Safety is a critical option choosing collector ring materials and manufacturing solutions. Influenced by the applying, the collector ring may be put through harsh surroundings, high conditions, or higher stress. It is vital to choose materials that will withstand these conditions and can perhaps not pose the safety hazard.

It is also imperative that you look at the use of environmentally friendly materials. Some collector ring materials could contain hazardous as chemicals which are toxic can harm the surroundings. By choosing eco-friendly materials, organizations can lessen their ecological influence and conformity with regulations.

How to Use Collector Rings?

Collector rings are used in lots of different applications such as wind turbines, elevator systems and cranes. The particular use of collector ring will dictate the needed conductivity use resistance and more qualities.

Once using a collector ring, it is important to check out the maker's directions very carefully. This might include cleansing regular maintenance and inspection. It is furthermore essential to assure that your collector ring is installed and all safety precautions is taken.

Service and Quality

When choosing the collector ring manufacturer, it is essential to give consideration to their amount of service and the quality associated with products. The reputable maker provide exceptional customer service, including technical help and warranty coverage.

The quality of the collector ring can influence their efficiency and service lives. It is necessary to select the Hydrogen coolers manufacturer helping to make use of top-quality materials and revolutionary manufacturing. Quality control measures, such as testing and inspection, ought to be in position and also to assure that the merchandise satisfies or exceeds markets criteria.

Applications of Collector Rings

Collector rings are used in several various applications, ranging from small motors to big industrial machines. Some applications that could be common cranes, wind turbines, robotics and elevators. The specific collector requirements will vary thinking about the applying, such as needed conductivity as temperature opposition.

Choosing the Best Solution for Your Needs

Whenever choosing a collector ring manufacturing and product solution, it is necessary to think about the particular specifications of one's application. Facets such as conductivity, wear resistance and ecological influence be carefully examined. Working by having a trusted manufacturer which offers high-quality goods and exemplary service could make sure that you choose the best collector ring solution for you personally.