Efficiency and reliability are important factors in the power generation world. Cooling systems with generators are needed to also run at a very optimal level since technology is getting better. A good example of these innovations are generator hydrogen cooling systems that certainly meet the level if not exceed it. These systems have their own characteristics, and advantages which are changing the scenarios of power plants across board. This study takes a deep-dive on the latest in hydrogen cooling systems, explains why leading suppliers choose hydrogen, provides an overview of reputable manufacturers and assists you with finding your perfect machine while also illustrating how new technology is improving generator operation.

Advances in Hydrogen Cooling

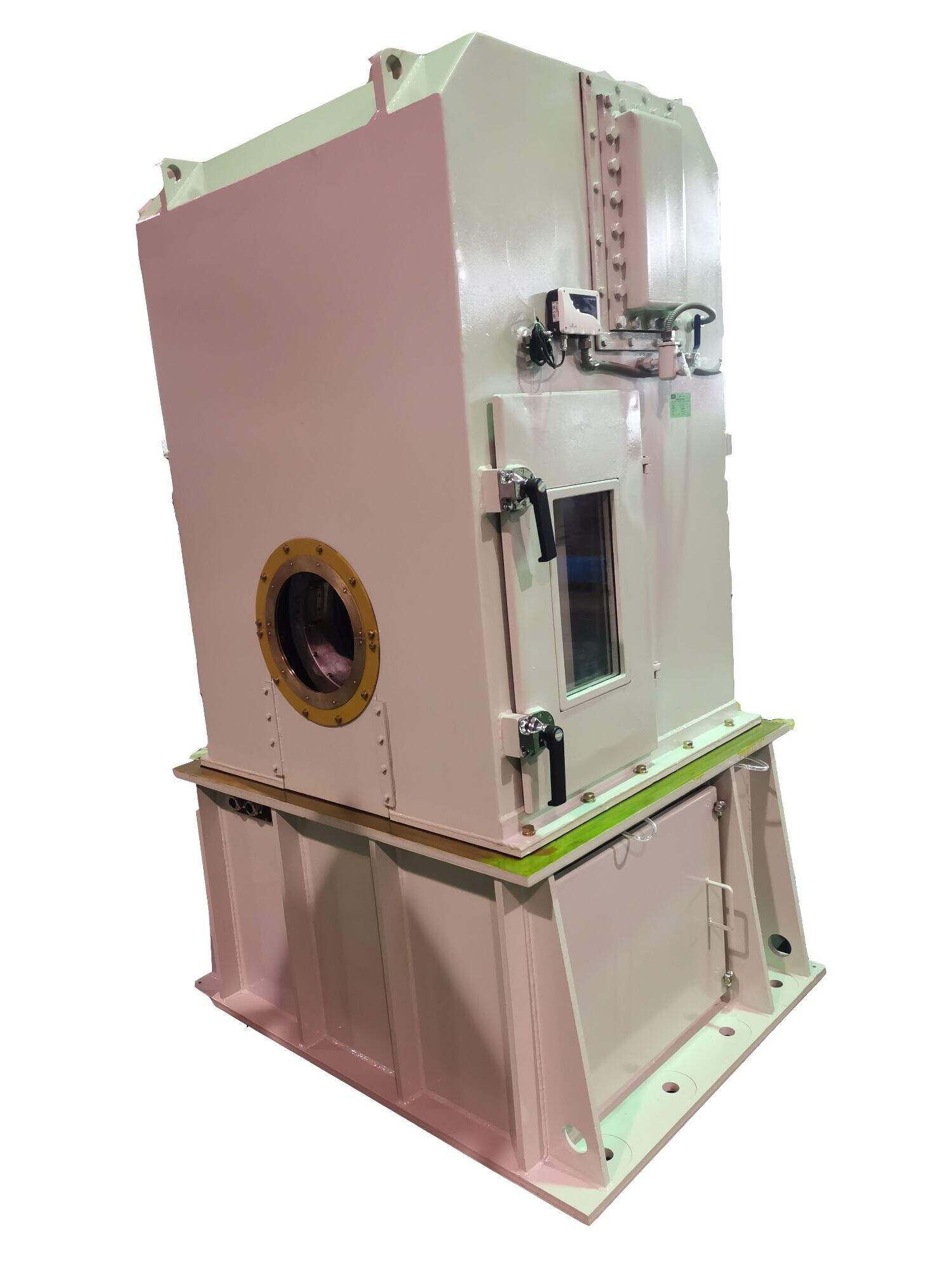

Hydrogen Cooling Systems - State-of-the-Art in Generator Technology Transformer Design and Specifications In comparison with air or water cooling methods, hydrogen offers a much higher thermal conductivity and there is also the added benefit of having low density that can help in transferring heat easily. Because of hydrogen, these systems are capable of absorbing and desorbing heat quickly which decreases the formation hot spots in generators by a lot. The Online platform can be accessesd at ( Fig able Purifier) Further developed configurations including hydrogen purifying units, lek discover the frameworks and cutting edge controls are utilised to keep up high immaculateness of inter impending through logical methods. By combining the two, the IoT working together with AI-driven monitoring and predictive maintenance, you fine-tune performance for high-efficiency operation while aiming at keeping production going in a virtually unbroken status.

Reasons Top Suppliers Sidelined Hydrogen Cooling

Hydrogen cooling systems offered high value benefits to the industry leading suppliers. To begin with, hydrogen has a high specific heat capacity allowing it to absorb more heat per unit volume than other coolants and therefore providing better cooling efficiency. Which translates directly into improved generator output and decreased fuel consumption, an economic factor that is key in a world of energy efficiency. Secondly, the very low molecular weight of hydrogen means it moves quickly providing even cooling across all windings in a generator and therefore keeps them longer operational. Also, it is non-toxic and environmentally friendly which fits with the global sustainability goals to make hydrogen cooling a choice of future.

The Hydrogen Cooling System Experts

Choosing a vendor of such advanced technology is not as simple and hence it should be considered pretty carefully. Any trusted name in the industry will have no trouble meeting such demands; their commitment to quality, innovation and excellent customer support is already on display. Such providers also put a great amount of effort into their R&D to keep on improving the support offered in order to keep it up-to-date with current industry standards. Choose suppliers who have a history in serving an evolving needs and requirements of each plant In particular, this means expert support is available after your hydrogen cooling product has been delivered to the plant for installation; technical back-up and maintenance should also be provided that reflects an intimate understanding of how all individual parts operate in order to maintain compatibility with others.

Learn More About Hydrogen Cooling System Best Practices Here

In this highly confusing world of hydrogen cooling systems, it is always important to know what you really want and that would be the first thing too. Keep in mind the size of your generator, permissive operating conditions and overall facility efficiency objectives. So, you must connect with the vendor who can provide sophisticated consultations and make sure for an accurate assessment of your demands. Nowadays most suppliers offer you online configurators and simulation tools, with which you can see how your system design might look like (visually) and then make appropriate adjustments before making a purchase. This makes it easy to find the perfect hydrogen cooling system for your application when you know what you need and have a reliable partner on-hand.

Next-Gen Hydrogen Cooling Technologies Optimise Generator Performance

Ongoing incorporation of advanced technologies will be the future for them as well! And even demonstrating innovations such as nanofluids — suspensions that include nanoparticles, and can improve heat transfer rates for better efficiency. Material science improvements also allow for generator components uniquely designed for hydrogen environments, which enhances wear and maintenance. Hydrogen cooling units provides required fast response and an excellent operation flexibility to support the integration of mainly intermittent renewables with increasing penetration.And due to rapid expansion for non-carbon power sources, hydrogen chillers are set up in strategic locations according this trend. All of this will be enabled by the adoption of next-generation technologies that represent a new era for energy management - one that moves power plants to never-before-seen levels of efficiency, reliability and environmental sustainability.

So in conclusion, generator hydrogen cooling systems have gone a long way to making power generation with the performance it is capable of - but also doing so sustainably! With the expanding evolution of technology, increased efficiency and operational flexibility is a possibility. Hydrogen cooling has the potential to continue having a critical place in power plants of the future, but only with robust collaboration and advanced solutions from an established partner.