The heavy reliance of modern society in electric generators is to a great extent due to the need for an uninterrupted electricity supply, especially when there is some pressure on power grid or location issues where sometimes it can weigh thousands of kilometeres. In that sense the internal hydrogen coolers are one of the most advanced technologies for turbine generator cooling systems ensuring long life and high performance. This makes these systems an all-in-one solution that increases the performance of a generator and is seen as one of the accomplishments in power generation technology and also helps in making it greener to protect our environment. This deep dive into an effective element of modern engineering explains how integral hydrogen cooling benefits system life and results in greener power generation with specific examples.

Hydrogenically Cooled Generators

But with very big electric generators, the ideal temperature balance is more like a golden mean as it represented above. The light weight and low viscosity of hydrogen, with its very high thermal conductivity in these temperature regimes make it an attractive coolant. For integrated hydrogen coolers automatically form part of the generator design and envelope, passing a cooling flow evenly around all-impedance critical stator (and rotor) windings through to tubular type system. By cooling it this way they prevent overheating and thus, possible damage to the interior parts of the generator. And prolonged system life due to maintaining the best operating temperature in all conditions via integral coolers this allows a stable electrical output.

Prolonging the Life of a Generator with Hydrogen Cooling

These have been used to benefit generator manufacturers by all but eliminating the thermal stresses associated with normal operation, increasing their lifespan exponentially instead. The challenges are primarily heating beyond what could be assumed to dissipated by purely passive means (conventional mode) due to insufficient air cooled systems. This results in faster degradation of insulation material and conductors than anticipated. But the fact that hydrogen is an excellent medium for transferring heat means any temperature changes can be done without stressing components such as has been known to happen with normal suburban natural gas, and this in turn does not require rapid temperature cycles which will ultimately destroy most of the other generator designs years before their time. In doing so, this conveniently prolongs your maintenance intervals and adds an extra layer of protection for both the lifecycle performance characteristics AND overall ROI on YOUR power generation asset.

Reasons For Using Hydrogen Cooled Generators In Terms Of Environment

Another product of importance that should not be overlooked are integral hydrogen cooling systems because they provide green technology when the world is increasingly focused on sustainability. Because the hydrogen cooling is a closed-loop, nearly all of the water can be recovered. Instead, it makes use of steam to turn mechanical turbines and generate electricity-no water is lost in this process; hydroelectric dams require the evaporation or processing (which also consumes prodigious amounts) consumed for nothing else but upkeep. Furthermore, hydrogen cooling has a high operational efficiency and therefore generators using this technology have lower fuel [consumption) to make power per unit of greenhouse gas emissions. Furthermore, this win-win combination not only helps to save water and reduce carbon footprints, hydrogen cooling is also the key component in future-orientated solutions for environmentally-friendly power generation.

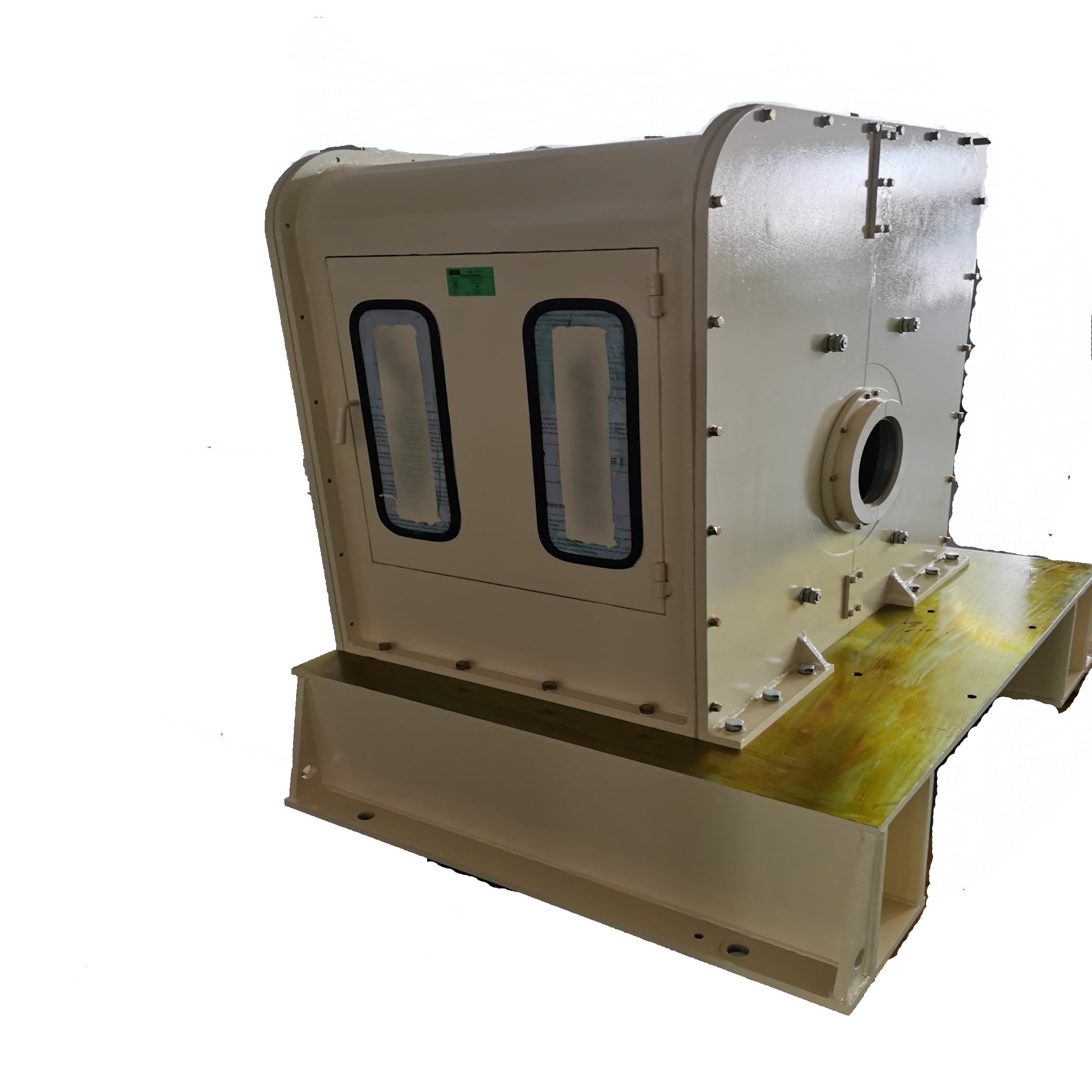

INTEGRAL HYDROGEN COOLERS FOR GENERATORS - AN ENGINEERING WONDERexploresys

Integral hydrogen coolers are a good example of this design and implement concept. Such materials will ensure long-term high-pressure hydrogen gas exposure conditions are safe for these valves to operate, as the advanced design of the new PIAs do. Precision-engineered heat exchangers provide a high rate of warmth transfer with low pressure drops, making it easy to cool off your engine. Also, the advanced monitoring and control systems keep running on continuous checking over hydrogen purity, pressure & temperature so that it can change in parameters before any abnormal condition happens. It has safety mode like anti-leakage detection wherein gates will be activated to warn operators at the earliest in case audible alarm pond is detected. This intricate combination of mechanical, chemical and control positions the integral hydrogen cooling system as a one-off amongst generators.

Application : Power Generation : Efficiency and Real world Case studies for Hydrogen Cooler Assembly

Bearing success of these in-service designs operational experiences is consistent with their theoretical advantages over non-Integral hydrogen coolings. One power station replaced outdated air-cooling systems with hydrogen-based versions, which boosted its efficiency by 15% just in the process of cooling down the generator. It resulted in much lower fuel consumption - and a correspondingly smaller CO2 figure. In a separate application, one large scale renewables site that adopted hydrogen cooling for its backup generators experienced the added benefit of all being kept just at room temperature -even in desert conditions- highlighting not only strong reliability gains but incredible fault-tolerant behavior over extreme-high ambient temperatures. Intangible triumphs include the benefits of Integral hydrogen cooling solutions in parallel to operating more sustainably as power plants trundle on.

Simply put, integral hydrogen cooler assemblies represent the ultimate progression in engineering that not only focuses on sustainability but also performance optimization for electric generators. They are not merely environmental conservation instruments but engines of economic progress and market integration, creating the backbone for active fossil-free energy assets on a global supply chain. These advances in cooling systems will undoubtedly be very efficient and useful as global energy needs grow, providing an adequate response to the problem at hand.

Table of Contents

- Hydrogenically Cooled Generators

- Prolonging the Life of a Generator with Hydrogen Cooling

- Reasons For Using Hydrogen Cooled Generators In Terms Of Environment

- INTEGRAL HYDROGEN COOLERS FOR GENERATORS - AN ENGINEERING WONDERexploresys

- Application : Power Generation : Efficiency and Real world Case studies for Hydrogen Cooler Assembly