How a Modified Brush Holder Structure Makes Collecting Carbon Emissions Safer

Perhaps you have seen sparks fly from the generator or engine? Are you aware those sparks could be dangerous possibly? They is due to carbon brushes which are acclimatized to conduct electricity through the rotating component of the machine to your fixed part. After a while, these brushes wear down and may cause the apparatus to malfunction or, in some full situation, beginning a fire. There the Rich modified brush holder structure in the collector ring shall are available. We will explain how this modification work and their importance for you.

Advantages of Modified Brush Holder Structure

The modified brush holder structure was created to lessen carbon brush ignition by reducing the probability of sparks. The main benefit the increased safety. Diminished risk of fire, specially when employed in engines with a high energy or in dangerous environments. It's an significant advantage heavy industry or machinery that runs 24/7. Not just is it safer, however the generator or engine utilizing this modification will furthermore likely has an extended lifespan, in turn reducing the requirement for frequent maintenance.

Innovation in Collector Ring Technology

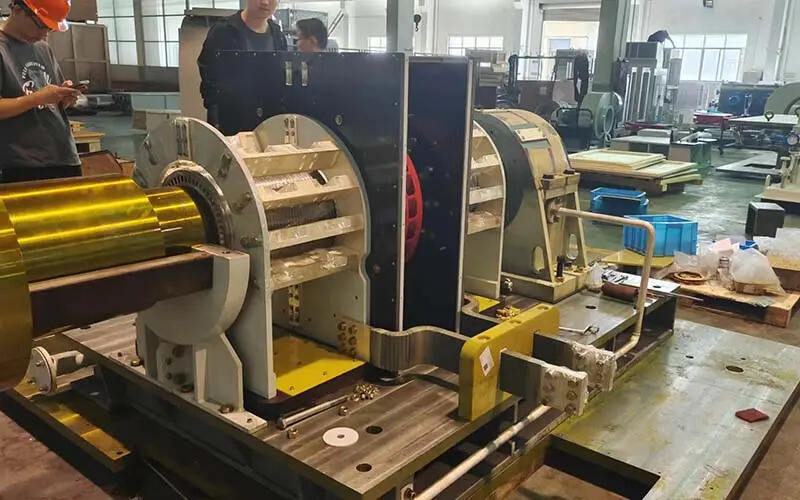

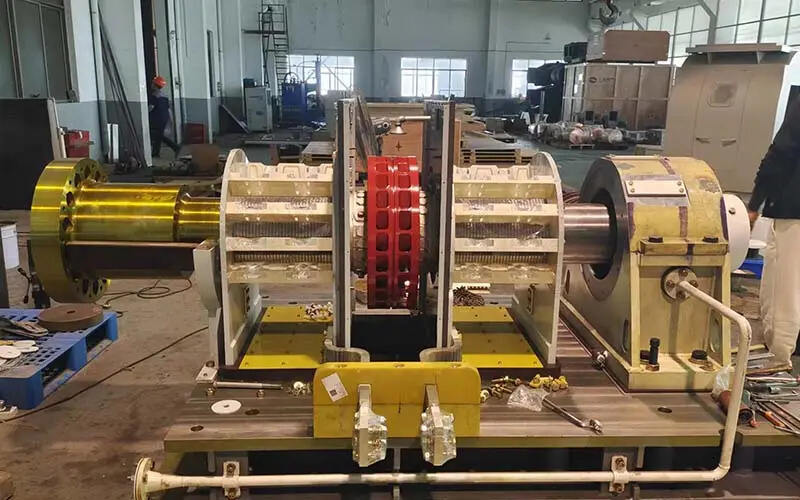

The brush holder structure when you look at the collector ring is one of the latest innovations in device technology. Designers and scientists doing work in this industry is increasing existing designs and advance safety and efficiency of electrical devices. The brush holder structure is only one of numerous elements into the collector ring, a circular device collects emissions produced through the procedure of a device which was electric.

Safety in Manufacturing with the Modified Brush Holder Structure

Manufacturing safety is of the value that will be utmost it boils down to heavy industries, where injuries might have significant consequences damaging people and assets. Just by applying this technology, you'll be able to instantly increase the safety of the center. Combining the collector rings modification of brush holder structure together with more innovations being technical automation will further enhance worker safety and effectiveness.

How to Use the Modified Brush Holder Structure?

The modified brush holder structure is straightforward to use. It may be incorporated into minimal strive to their machinery. A taught professional install the modification using simple tools or because of the assistance of mechanical installation jigs which can be increasingly available in lots of parts associated with the planet. Consult an experienced professional or your motor's manufacturer to put in the structure properly.

Quality and Performance

The modified brush holder structure was the high-quality product which meets the exacting requirements of production and regulatory compliance. Durable, and developed to final and due to this, need minimal maintenance ensuring efficient and trouble-free operation. The Hydrogen coolers technology has an great return investment making the surplus expense worthwhile in the long run by reducing the requirement for expensive fix efforts or downtime.

Application in High-Performance Machinery

The modified brush holder structure could be employed to a vast mixture of machinery run at high speeds and Brazed Plate Heat Exchanger production levels. Examples add engines in heavy machinery, oil rigs, locomotives, SAG mills, pumps, and generators found in wind farms. Anywhere a decrease in sparking may improve the safety or effectiveness of an electric device, this technology is definitely an tool which can be indispensable.