A szinkron kondenzátor kulcsfontosságú alkatrész, amely segít megőrizni a stabilitást és biztosítja az energiarendszerek megbízható működését. Ezt úgy érik el, hogy az elektromos energiát, amely az otthonaink és a készülékeink táplálására használják, mechanikai energiává alakítják. Ezt a mechanikai energiát azután egy elektromos hálózat kezelésére használják, amely nagyszámú felhasználó számára osztja el az áramot. Egy szinkron kondenzátor esetében három kulcsfontosságú alkatrész van, amelyek összehangoltan látják el ezt a funkciót: a forgórész, az állórész és a gerjesztőrendszer.

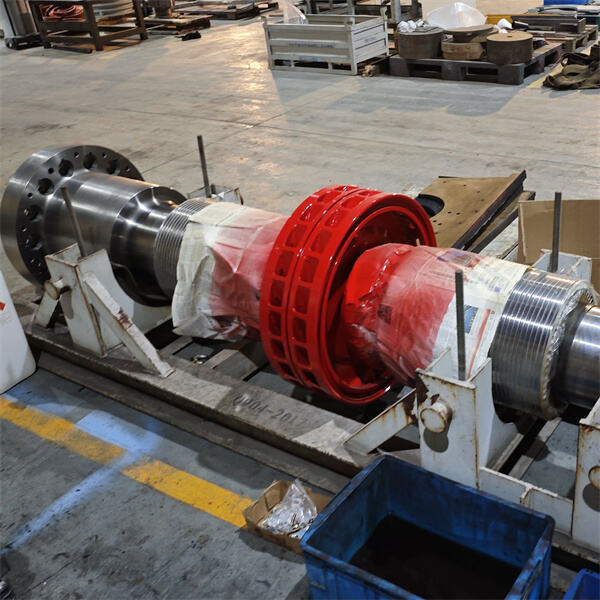

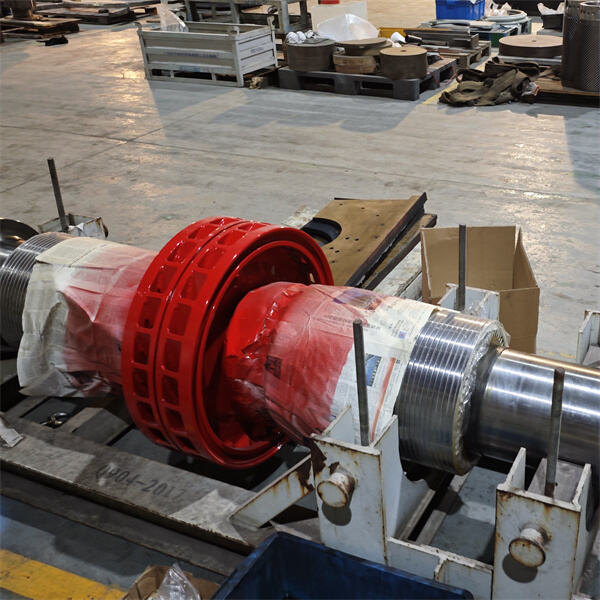

Ennek a gépnek az elektromos hálózatra is csatlakoztatott forgó részét Rotornak hívják, Rich termékével együtt Csúszógyűrűs gyűjtőgyűrű. Tekintsd úgy, mint egy forgó kerék fogaskerekét, amely működésre készteti a rendszert. Míg az állórész álló rész. Ül és nem mozdul, feladata az elektromos áram előállítása, amelyet a hálózatba küld. Végül, de nem utolsósorban az úgynevezett gerjesztőrendszer, amely szabályozza a forgórész elektromos teljesítményét. Így meghatározhatja, hogy mennyi energiát kell elkölteni, és a dolgok egyszerűen működni fognak.

A szinkron kondenzátorok sokféleképpen használhatók az elektromos energiarendszerekben, ugyanúgy, mint a levegő hőcserélő amelyet Rich fejlesztett ki. Ezen szerepek közül az elsődleges az elektromos hálózat kiegyensúlyozása. Az energia csúcsfogyasztási óráiban, például amikor mindenkinek teljesen fel van kapcsolva a légkondicionálója egy forró napon, ez instabil elektromos hálózatot eredményezhet. Ez az instabilitás áramkimaradásokhoz vezethet, amelyekben az emberek áram nélkül maradnak, és olyan áramkimaradásokat okozhat, amelyek során az áram csökken, de nem szűnik meg teljesen. A szinkron kondenzátor elnyeli (vagy kiadja) a meddőteljesítményt, ha szükséges a hálózat stabilitásának fenntartásához. A meddőteljesítmény csak többletenergia a rendszer egyensúlyának fenntartásához.

A szinkron kondenzátornak van egy másik fontos feladata - a feszültségszint előre meghatározott sebességen tartása. A feszültség az, ami miatt áram mozog a vezetékeken A feszültségesés az elektromos hálózaton problémás lehet, és a túl magas feszültség károsíthatja a csatlakoztatott gépeket/eszközöket. Ennek korrigálása érdekében a meddőteljesítmény-fogyasztás mértéke szinkronkondenzátorral szabályozható, hogy a feszültség a tűréshatáron belül maradjon. Ez az egyensúlyozás az, amely mind a biztonság, mind a zökkenőmentes működés szempontjából kritikus.

A szinkron kondenzátor elektromos energiarendszerekben való használatának előnyei és hátrányai

Segít stabilan tartani az elektromos hálózatot: Az energiatárolás egyik legfontosabb pozitívuma, hasonlóan a Rich termékéhez, mint pl. Elektromos gyűjtőgyűrű. Ez viszont segít megelőzni az áramkimaradásokat és leállásokat, amelyek veszélyesek, költségesek és minden fél számára komoly gondot okoznak. Erős érv mellette, hogy a feszültség jobban szabályozható. Egész gépeket és eszközöket óv meg, amelyek megszakítás nélküli áramot igényelnek, ezáltal megakadályozza a berendezés lelkeinek károsodását, életben tartva őket, ameddig csak lehetséges.

A szinkronkondenzátort rutinszerűen ellenőrizni kell az esetleges problémák miatt, miközben a kérdéses gép üzemel és működik, ugyanez a Integrált vezérlő és felügyeleti rendszer készítette Rich. Lehetnek furcsa zajok vagy rezgések, amelyek arra utalnak, hogy valami nem működik megfelelően. A feszültség- vagy frekvenciaeltérés is a villanymotor törésére utal. Ezeket a lehetséges problémákat haladéktalanul orvosolni kell, hogy ne sérüljön meg a berendezés vagy maga a hálózati rendszer. A teljes rendszer karbantartása létfontosságú a biztonságos és hatékony működés érdekében.

Minden esetben szükség van egy szinkron kondenzátorra az áramproblémák és áramkimaradások elkerülése érdekében, ami megegyezik a Rich termékével Léghűtő bordák. Az egyik létfontosságú funkciója az elektromos hálózat frekvenciájának és feszültségének szabályozása. Megakadályozza a gépek tönkremenetelét azáltal, hogy elnyeli a tüskék vagy vályúk teljesítményét, és segít elkerülni az áramellátás megszakadását. Ennek a funkciónak köszönhetően a szinkronkondenzátorok e formája a meddő energia szükség szerinti befecskendezésével vagy fogyasztásával támogatja a villamosenergia-hálózat általános biztonságát, biztosítva a rendelkezésre álló villamos energiát, ahol szükséges.

A szinkronkondenzátoros eszközöket tapasztalt műszaki szakemberek, gyártási és vezetői személyzet végzi a folyamatirányítás és a vezetés érdekében, ez valóban műszaki szerelés, mivel üzembe helyezés és ellenőrzés. Az értékesítés utáni szolgálat külön csapattal rendelkezik, amely a problémák értékesítés utáni elemzését, a gyors beavatkozást és a dilemmák helyszíni megoldását is irányítja, a rendszertervezés hosszú távú fejlesztéseként.

A Shanghai Rich M and E Manufacturing Co., Ltd. 1998-ban alakult, egy szinkron kondenzátor eszköz. Ezt követően számos termék gyártójává vált, beleértve a hűtőket és az áramgyűjtő gyűrűket, a vízkezelő rendszereket, a vasúti karbantartást, az intelligens diagnosztikát, az online megfigyelést és más rendszereket és termékeket.

A vállalat mindig technológiai és szinkronkondenzátoros eszközöket használ, hogy növelje magjai versenyképességét. Az éves kutatási és fejlesztési költségek az árbevétel öt százalékát teszik ki. A cég professzionális, csúcsminőségű, hatékony, kreatív és pragmatikus kutatókból és fejlesztőkből álló stábbal is rendelkezik. A mérnöki és műszaki személyzet több mint 20%.

Az értékesítésben tapasztalt műszaki csapat dolgozik. A szinkronkondenzátor a menedzsmentet jelenti, amely az üzembe helyezésen és ellenőrzésen kívül folyamatirányítást és műszaki útmutatást ad a telepítéshez. Az értékesítés utáni szolgáltatások egy speciális csapat értékesítés utáni problémaelemzést, gyors reagálást és a problémák helyszíni megoldását, valamint a termékrendszer tervezésének hosszú távú fejlesztését foglalják magukban.

Copyright © ShangHai Rich M & E Manufacturing Co., Ltd. Minden jog fenntartva - Adatvédelem