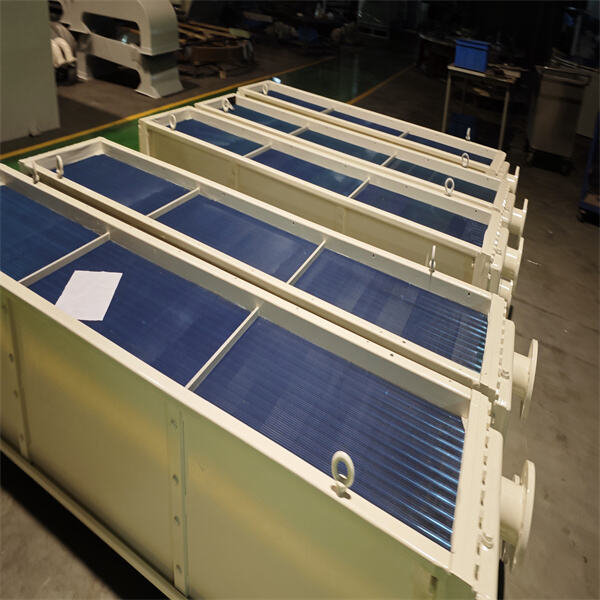

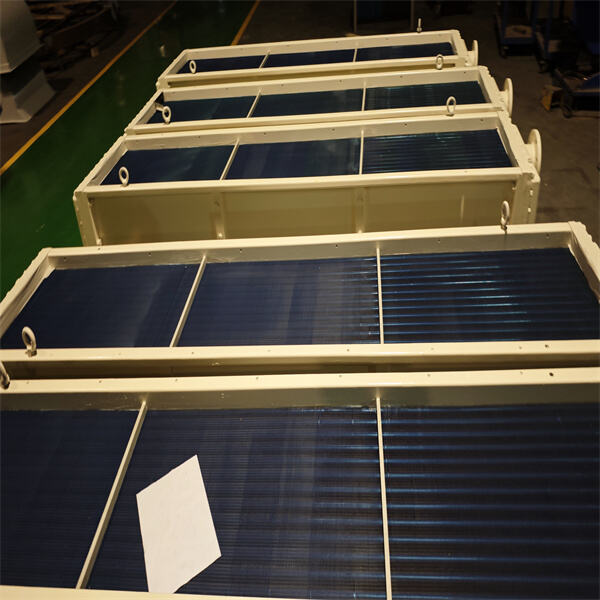

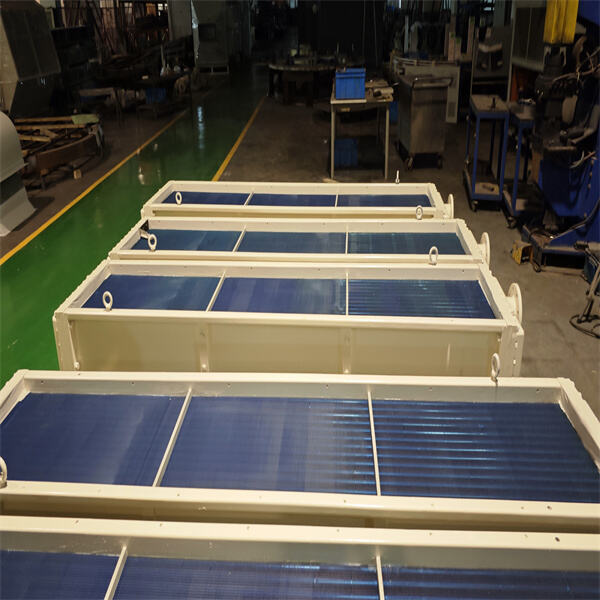

Penukar Panas adalah mesin luar biasa yang membantu mentransfer panas dari satu tempat ke tempat lain. Mereka memainkan peran penting di beberapa industri beragam di mana mereka dapat menghemat energi sambil membuat proses bisnis lebih lancar. Rich penukar panas fin aluminium — Ini adalah salah satu heat exchanger yang paling umum digunakan. Lanjutkan membaca untuk mengetahui lebih banyak tentang apa itu perangkat ini dan bagaimana cara kerjanya. Heat exchanger pelat fin aluminium, sebagai bentuk heat exchanger, dapat mentransfer energi dari fluida panas ke fluida dingin atau sebaliknya tanpa mencampur keduanya. Hal ini melibatkan lapisan-lapisan pelat tipis, masing-masing berorientasi pada arah tertentu. Penempatan unik sel-sel ini kemudian menciptakan saluran atau jalur yang dapat dilalui oleh fluida. Celah-celah ini memiliki sirip tersembunyi di dalamnya, yang merupakan semacam puncak miniatur yang memperluas permukaan pelat. Permukaan yang luas memfasilitasi transfer panas yang lebih baik dengan sedikit kerugian dengan memungkinkan aliran panas yang baik antara fluida.

Penukar panas dengan pelat alumunium dan sirip sangat ideal untuk digunakan di berbagai industri, dan mereka sangat baik karena banyak alasan. Keuntungan utamanya adalah memiliki efisiensi yang lebih baik. Mereka juga dirancang untuk memberikan tingkat transfer panas tertinggi, sehingga menghemat banyak energi. Bisnis menjadi lebih menguntungkan, sehingga harga bisa lebih rendah. Mereka juga sangat kokoh dan tidak berkarat, yang membuatnya ideal dalam lingkungan keras di mana banyak bahan lain akan gagal. Keterampilan dari penukar panas ini adalah keuntungan besar lainnya. Mereka digunakan dalam berbagai aplikasi mulai dari sistem pemanasan dan pendinginan hingga proses kimia yang berbeda. Mereka juga dirancang agar kecil dan ringan, yang membuatnya cukup fleksibel untuk dipasang di tempat-tempat berbeda dan dibawa jika diperlukan. Kemampuan ini berguna, tetapi di perusahaan yang memerlukan mesin untuk melakukan fungsi yang berbeda, hal ini bisa jauh lebih membantu.

Aplikasi penting dari heat exchanger pelat aluminium dengan sirip adalah mendinginkan uap yang terbentuk selama pembangkitan energi di pembangkit listrik. Ini Rich heat exchanger plat fin aluminium dijepret mendinginkan uap dengan sangat efisien sehingga membantu meningkatkan efisiensi pembangkitan energi secara keseluruhan. Ini berarti bahwa penghematan energi lebih baik untuk ibu bumi dan laporan laba rugi juga.

Heat exchanger ini juga sangat penting dalam bidang manufaktur kimia. Sebaliknya, mereka mendinginkan dan mengkondensasi bahan kimia saat sedang dikembangkan dalam proses manufaktur. Mengenai bahan kimia ini, jumlah energi yang lebih kecil diperlukan untuk mendinginkannya dengan menggunakan heat exchanger pelat sirip aluminium. Ini menghemat biaya, meningkatkan efektivitas yang mempermudah proses manufaktur.

Heat Exchanger Pelat Sirip Aluminium — dirancang untuk aplikasi tekanan tinggi yang membutuhkan ketahanan dan efisiensi energi. Rich pertukaran panas aluminium brazed sering digunakan untuk mendinginkan dan mengkondensasi gas yang keluar dari proses pengeboran minyak. Penukar Panas Kimia: Pada saat yang sama, penukar panas ini juga ditemukan di dalam pabrik pengolahan kimia di mana pendinginan dan pengkondensasian berbagai bahan kimia yang diproduksi di fasilitas tersebut.

Perusahaan selalu memiliki penukar panas fin plat alumunium dan kemajuan ilmiah untuk meningkatkan daya saing intinya. Biaya penelitian dan pengembangan tahunan mencapai 5 persen. Perusahaan juga memiliki staf profesional, berkualitas tinggi, inovatif, dan pragmatis dalam tim penelitian dan pengembangan. Staf teknis dan insinyur perusahaan lebih dari 20 persen.

Penukar panas pelat alumunium dengan fin biasanya berada dalam posisi untuk memberikan solusi satu atap kepada pelanggan juga karena layanan produk yang komprehensif dan tim pra-penjualan yang terdiri dari ahli di bidang teknis untuk menghasilkan pelanggan serta solusi kerja sama desain dan sistem; Penjualan memiliki teknisi, supervisor, dan tenaga manufaktur yang memenuhi syarat untuk memberikan kontrol proses, bimbingan pemasangan, dan pelatihan teknis serta penyesuaian dan pemeriksaan. Layanan purna jual mencakup situs khusus yang menganalisis masalah kualitas setelah penjualan dengan respons cepat dan penanganan masalah kualitas yang muncul di lapangan, serta perbaikan jangka panjang pada desain.

ShangHai Rich M and E Manufacturing Co., Ltd. Didirikan pada tahun 1998, merupakan perusahaan yang telah beroperasi selama 20 tahun. Sejak itu, perusahaan ini telah menjadi produsen heat exchanger plat alumunium dengan sirip untuk berbagai macam produk seperti cooler dan power collection rings, perangkat pengolahan air, pemeliharaan rel kereta api, diagnosis cerdas secara online, serta sistem dan produk lainnya.

Heat exchanger plat alumunium dengan sirip memiliki tenaga teknis ahli, staf produksi dan manajemen untuk kontrol proses dan bimbingan teknis dalam pemasangan, pengecekan, dan pemeliharaan. Layanan purna jual memiliki tim yang antusias yang pasti bertanggung jawab atas masalah-masalah yang muncul setelah penjualan, respons cepat dan penanganan masalah di lokasi serta perbaikan jangka panjang dalam desain sistem produk.

Hak Cipta © ShangHai Rich M & E Manufacturing Co., Ltd. Semua Hak Dilindungi Undang-Undang - Kebijakan Privasi